Battery tray business

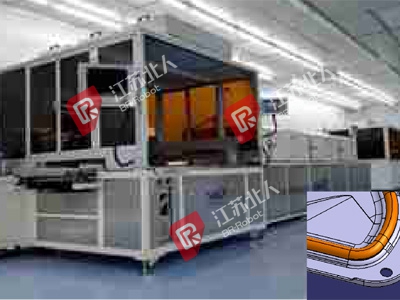

In 2015, Jiangsu Beiren began researching the manufacturing process of production lines for new energy battery trays. Through years of experience accumulation and R&D, they have provided automated production lines for various new energy battery trays to companies such as SAIC Group, Tesla, Nissan, CATL, and Hongqi, including models like Roewe, Tesla Model 3, Model Y, Hongqi, and Nissan. This has earned them strong customer recognition and established a solid industry reputation. In the battery pack field, they have completed a complete set of design and manufacturing processes, including arc welding, FSW, FDS, SPR, laser wire filling welding, gluing and curing, airtightness testing, cleaning, spot welding, CNC machining, and online inspection, providing customized complete process solutions for their customers. In the lithium battery module line, the new energy vehicle lithium battery module line integrates key technologies such as flexible manufacturing, intelligent logistics, and digital information automatic collection and integration, promoting the innovative application of safe and controllable core intelligent manufacturing equipment such as industrial robots, intelligent vision systems, intelligent sensing and control equipment, intelligent testing and assembly equipment, and intelligent logistics and warehousing equipment. They are developing automated, informatized, digitized, and intelligent production lines for multi-specification new energy vehicle lithium battery systems.

While continuously increasing its market share in intelligent production lines for new energy battery trays, Jiangsu Beiren is also actively expanding into new areas, successfully entering the CATL supplier system and participating in the design and manufacturing projects of multiple module production lines. In 2021, Jiangsu Beiren began to increase R&D investment, continuously expanding in the new energy market, and actively participating in overseas market expansion while maintaining its domestic market.

Jiangsu Beiren has many years of experience in aluminum alloy connection technology and possesses rich project implementation cases for aluminum alloy CCB, aluminum alloy bumpers, aluminum alloy chassis, aluminum alloy car doors, and aluminum alloy battery packs, providing professional and efficient solutions.

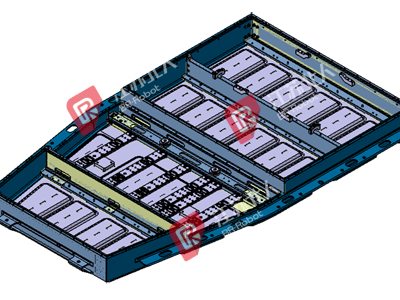

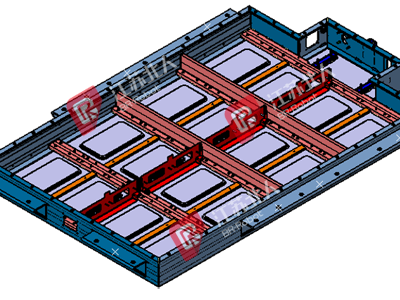

Designed Production Capacity: 8 Main Process Types: Arc welding, friction stir welding, machining, drilling and tapping, cleaning, gluing, assembly, etc.

Designed Output: 8 Main Process Types: Arc welding, friction stir welding, machining, drilling and tapping, cleaning, gluing, assembly, etc.

400-1016-959

400-1016-959 Map

Map